A NEW VERTICAL: MATERIAL HANDLING

Leveraging the A.I navigation system, used to automate the preceding large floor scrubbers, the task was to design and develop a commercial delivery vehicle that could operate in dynamic commercial environments. This b2b vehicle is Auto Delivery.

Announced spring 2019, the first target customer for Auto Delivery was Walmart. The delivery vehicle will help sales associates and backroom stockers, move materials and merchandise throughout the store.

PROBLEM STATEMENTS

In large retail stores, sales associates spend a monumental amount of time and energy transporting merchandise to various parts of the store. This is physically taxing and time consuming. Carrying and pushing heavy loads of merchandise can also increase risk of injury.

There are certain high volume products that require constant restocking. Keeping up with customer activity, by readily having stock unpacked and brought to the sales floor is also challenging.

When sales associates are occupied with moving merchandise and stocking, they are losing face time and are less available to customers, who may need assistance. This affects sales.

During restocking products, many aisles have a buildup of recyclables that need to be taken to the back of the store.

—

Design and develop a robotic solution that:

Can help sales associates move high volumes of merchandise/materials around the store, so that they are freer to assist customers.

WHO WILL USE AUTO DELIVERY?

First tier users: Sales associates, managers, merchandise stockers, truck unloaders.

Second tier users: Store customers,

MY ROLES

Lead UX Research & Testing

Market Research

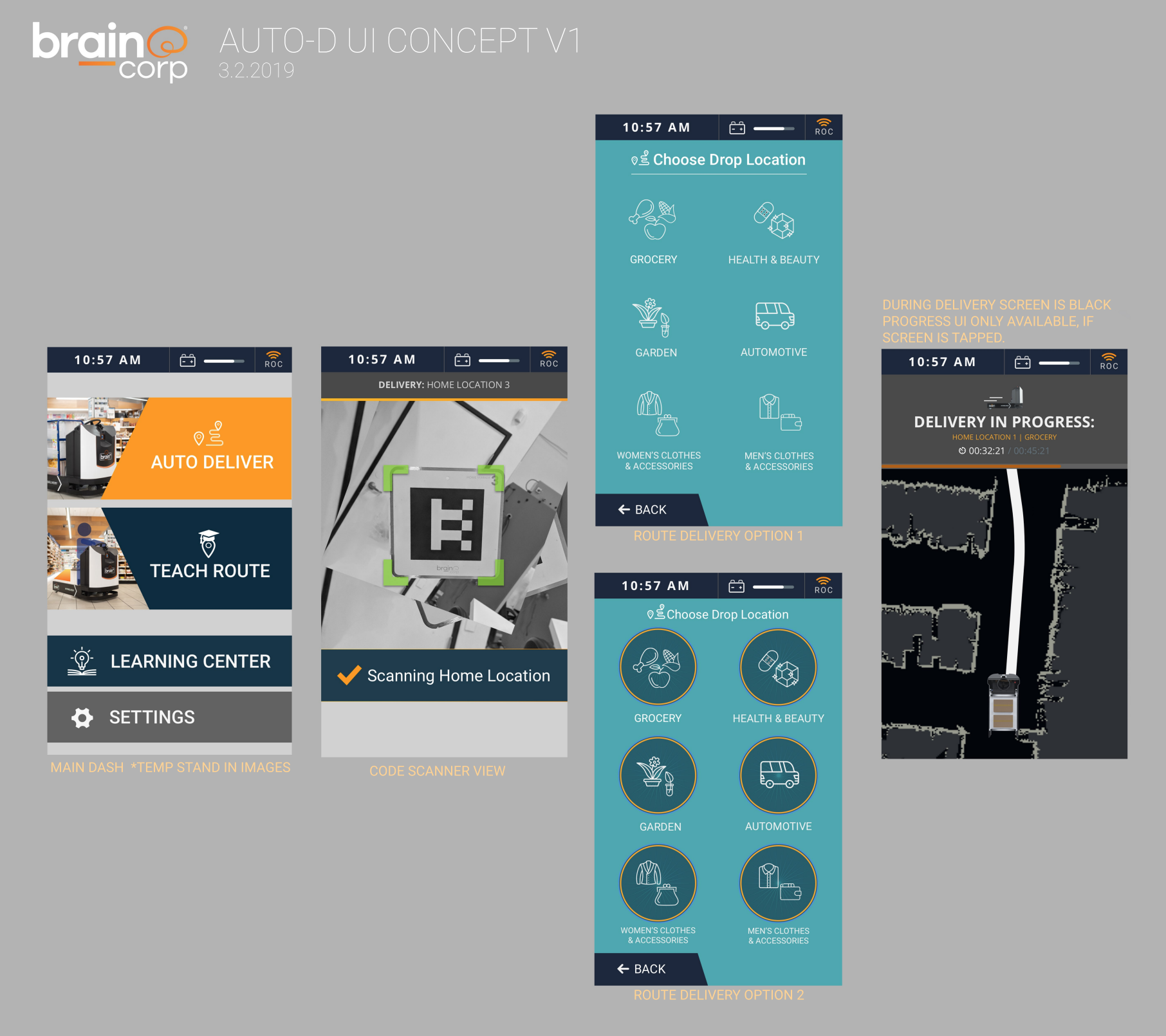

Lead Human : Robot Interaction Design (sound/lighting/UI)

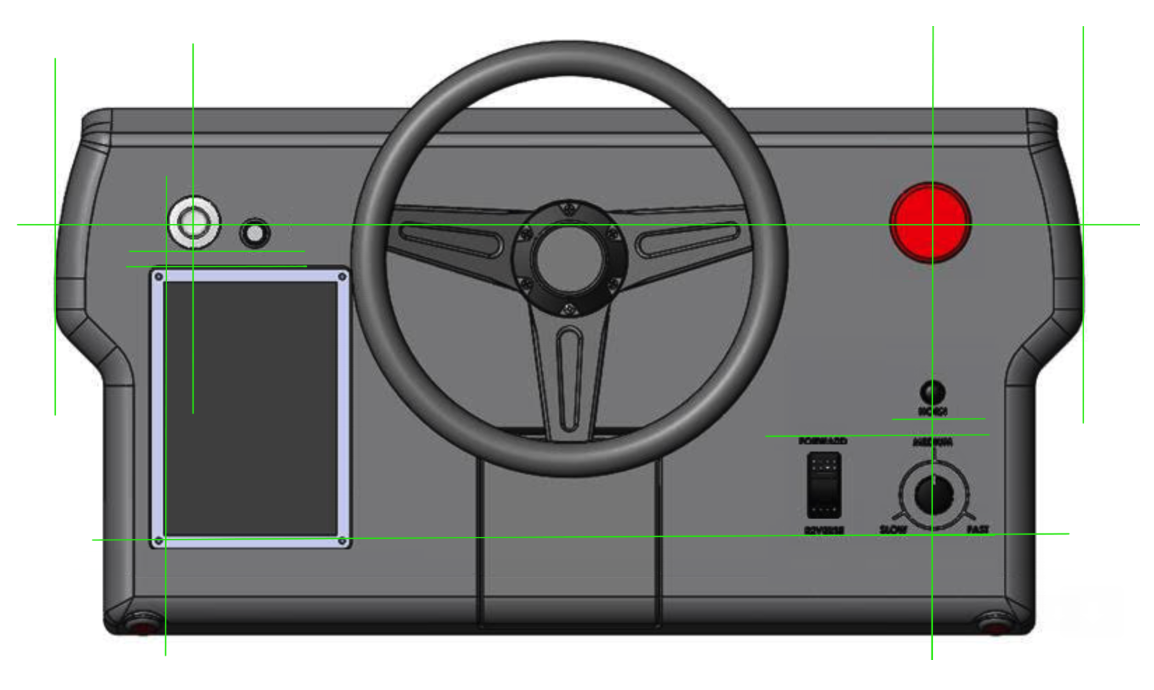

Hardware UX (Ergonomics, movement, environment functionality, visual design & communication, performance)

Lead UI Design Direction

Research and testing were conducted in parallel with R&D motion planning scientists and software engineers.

SCOPE AND CONSTRAINTS

Timeline for design and development of the beta units is very short, ~8mo.

User workflow is very different from that of robotic floor scrubbers.

Robot will be operating at all hours, including peak customer hours.

Control research and testing stores are in Calexico & El Centro (1.5-2 hr drive)

DESIGNING A DELIVERY ROBOT: THE DISCOVERY JOURNEY

Designing for Auto Delivery was challenging and incredibly fun because in many aspects, it was a brand new robot tasked with a job unlike any of the preceding floor care robots. Not just autonomously navigate and operate in dynamic environments, but to deliver merchandise and handle the transport of materials. From research, to prototype and to the deployment of beta robots, here are highlights from designing the Auto Delivery.

ENVIRONMENT STUDIES

This initial phase involved studying Walmart’s various store types and conducting feature and layout inventory. This study helped to categorize situational navigation challenges like tight turns, product placement obstacles, product demo traffic, high volume customer traffic and safety implications like overhanging merchandise or the frequent presence of small children or animals.

ASSOCIATE WORKFLOW STUDY

In order to design an effective solution to help associates with merchandise and material handling, I first had to understand their workflow, pain points and the end to end journey of a product, from truck to sales floor.

The first step was becoming an understudy to the sales associates, shadowing their work in the back room and helping to stock items. From this I was able to document a workflow, that the Auto Delivery would be integrated into. This study also helped to provide knowledge into their inventory structure and high volume merchandise, which are the priority for delivering to the floor.

Understanding the flow of traffic and merchandise helped to design the Auto Delivery’s workflow, from location of storage, to establishing the best journey routes throughout the store.

Studying the flow of inventory, quantifying how many pallets & carts are filled per truck delivery, created a baseline performance metric for the Auto Delivery.

CUSTOMER STUDY

Before the initial Beta units were tested in stores. I conducted customer behavioral studies. The first one being a time study. Over the course of two weeks, I surveyed high traffic “racetrack” aisles, along popular departments like grocery, toys and healthy and beauty and got varying time metrics measuring how long customers lingered in one spot before moving. I re-ran this test, once we deployed the robot and took measurements to see if there was a difference in behavior.

KEY RESULTS

Customers spent more time in one spot, with no robot around. When the robot is operating and approaching, customers felt the need to move, but did not know which way to move, so they would inch back and forth, depending on the robot’s sounds and behavior. This lead to two design enhancements highlighting directional intent on the robot and changing navigation behavior when approaching moving obstacles (people/carts).

Gathered observational data on customer reactions to the robot and categorized them (surprised, ignore, afraid, curious). Most individuals were either curious or ignored the robot.

Gathered observational data on customer reactions to the operational warning sound (alarming beep). Customers were annoyed and expressed heightened anxiety, when the robot would beep by them. The function of the beep was successful, which is to get the attention of those in the environment, but it did not garner a positive response. This lead to an extensive sound study.

HEARING AUTO DELIVERY - A SOUND STUDY

Objectives

To gain a deeper understanding around the operational behaviors, of the Auto Delivery, that would benefit from sound association. Gather a baseline of sound parameters like tempo, pitch and volume that incite customer reaction, but does not garner joyful or curious behaviors, where people would want to interact with the robot and does not garner a negative reaction, where the sound would cause annoyance or anxiety.

Participants

Walmart sales associates, cleaning staff, managers, stockers

Test Outline

Participants were played a selection of sounds. They were told these sounds were random, but they were based on an initial organization of sounds, I had put in the following categories

Delivery - Any sounds that could be associated with tug in any part of the delivery process ie confirmation, about to deliver,

Operational - Any sounds that take place while the tug is traveling in autonomous mode, outside of delivery or arriving at home.

Error or Assist - Any sounds that indicate the machine may need help or that an error has occurred.

Doesn’t apply to any (non disclosed bucket to participants) - I kept this to notate when participants could not find a place for any sounds, but didn’t disclose it, to force further thinking upon each sound, before giving up.

Participants were then asked

How does it make you feel? ( to classify spectrum of anger, indifference to delight.

What does it mean?

Study results

Constant sounds that don’t change in pitch or tempo become like sound pollution and eventually become ignored.

A slow increase in volume, as the robot approaches people, would mimic real world safety patterns like cars or forklifts reversing and only communicate intensity when required.

Having sound escalate in volume and severity, depending on the obstacle would be helpful in offering sound variety, while still maintaining the same type of sound for familiarity.

A collection of sounds were selected from testing, for robot beta testing in store, for longer a longer term study.

Associates like that people currently noticed the beeping and associates notice people moving. Though it annoys them, they’re glad from a safety reason, it’s loud enough to be noticeable.

ROBOT AND HUMAN WORKFLOW

Over the course of summer to fall, the employee and store workflow research evolved into one that included the robot’s integration. Through teaching the Walmart associate teams on how to use the delivery robot and integrating the robot into their day to day tasks, we were able to get valuable feedback that was integral to iterating quickly to prioritize performance and efficiency.

Workflow Goals

Minimize impact and disruption to the associates work life.

Increase merchandise delivery capacity.

Save associates X number of steps daily.

Integrate physical workflow with a new software workflow, to decrease robot idle time and increase delivery efficiency.

Save associates time in merchandise delivery.

RESULTS AND WHAT’S NEXT?

Successful POC deployment of beta robots operating at Walmart stores around the country.

To date over 3900 carts have been delivered and over 1.4 million associate steps have been saved.

Successful launch in a new vertical outside of floorcare - material handling.

From beta to production, development for production robots are now underway.

Media publications:

https://techcrunch.com/2019/04/02/brain-corp-debuts-an-autonomous-delivery-robot-for-factories-and-retail/

https://venturebeat.com/2019/04/02/brain-corp-unveils-an-autonomous-delivery-robot-for-retail-stores-warehouses-and-factories/

https://www.sandiegouniontribune.com/business/technology/story/2019-09-10/can-san-diegos-brain-corp-become-the-microsoft-of-self-driving-robotsChanges to sound, based on the sound studies, has increased customer satisfaction, decreased sales associate confusion (due to multiple industrial machines having similar alarming sounds) and has lead to varying sound being an integrating feature on the platform.

CREDITS

3D Animations - Jimmy Kim

Robot Industrial Design and Machine Style - Jimmy Kim and Nikola Simic